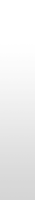

The typical electrical contractor's revenues break down

According to National Electrical Contractors Association (NECA) data, the typical electrical contractor’s revenues break down like this graph.

As shown in the graph, material and labor costs have the greatest impact on your profitability.

It’s estimated that approximately 40% of the total labor cost can be attributed to material handling: receiving, unpacking, storing, assembling, ordering, returning, moving or locating.

SOURCE: Agile Construction for the Electrical Contractor by Dr. Perry Daneshgari